Apg100-mp Non-linear Pirani Gauge Nw16

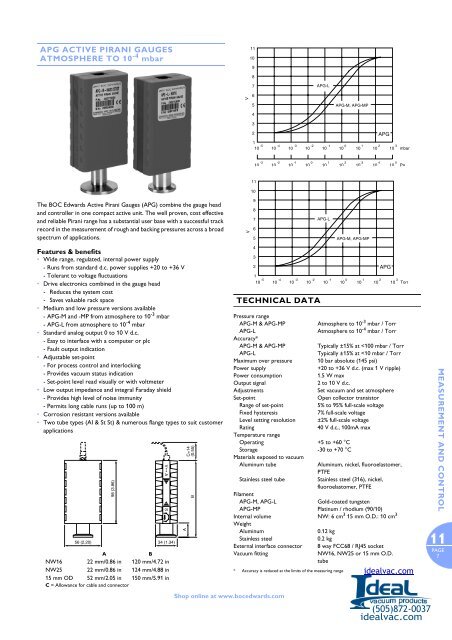

. Wide range, regulated, internal power supply - Runs from standard dc power supplies +20 to +36 V. Tolerant to voltage fluctuations. Drive electronics combined in the gauge head - Reduces the system cost. Saves valuable rack space. Medium and low pressure versions available - APG-M and -MP from atmosphere to 10 -3 mbar.

APG-L from atmosphere to 10 -4 mbar. Standard analogue output 0 to 10 V dc - Easy to interface with a computer or plc. Fault output indication. Adjustable set-point - For process control and interlocking. Provides vacuum status indication. Set-point level read visually or with voltmeter.

Low output impedance and integral Faraday shield - Provides high level of noise immunity. Permits long cable runs (up to 100 m). Corrosion resistant versions available. Two tube types (AI & StSt) & numerous flange types to suit customer applications.

Pirani Gauge Definition

Ionization Gauge

Edwards Active Pirani Vacuum Gauge APG-MP Active Pirani Vacuum Gauge contains a NW16, KF16 vacuum flange, is compact for easy installation, has a linear output. The new Edwards gauges are compatible with all Edwards TIC, ADC, TAG instrument controllers and other active gauge controllers and displays. They are also CSA, C/US approved as well as fully RoHS compliant due to their lead-free construction.

Apg100-mp Non-linear Pirani Gauge Nw16 Range

They measure pressure from 1000 down to 10 -3 Torr. The signal cables and TIC vacuum gauge controllers are sold separately. The instruction manual for these Edwards APG-MP series gauges is available in PDF format below. This gague contains a Platinum / rhodium (90/10) filament and can measure pressure down to 10-3 Torr and is stainless steel. These Edwards APG-MP Active Pirani vacuum gauges has a KF16 NW16 vacuum flange are new with Edwards part number D02185000.If you connected the APG to a Edwards AGC controller orAGD display, use the set-point adjustment proceduredetailed in the instruction manual supplied with theunit. If you connected the APG to your own controlequipment, use the procedure on page 22 of the manual.pdf below.

The APG-MP can be mounted in any orientation however the gauge tubes are individually factory calibrated in nitrogen whilst vertical. For correct pressure indication in your chosen gauge orientation, the gauge should be recalibrated at atmospheric pressure. Edwards recommends mounting the gauge tube vertical in order to minimize the build up of process particulates and condensable vapors within the gauge. The APG MP is calibrated for use in nitrogen, and will read correctly with dry air, oxygen and carbon monoxide.